Pipe Prefabrication

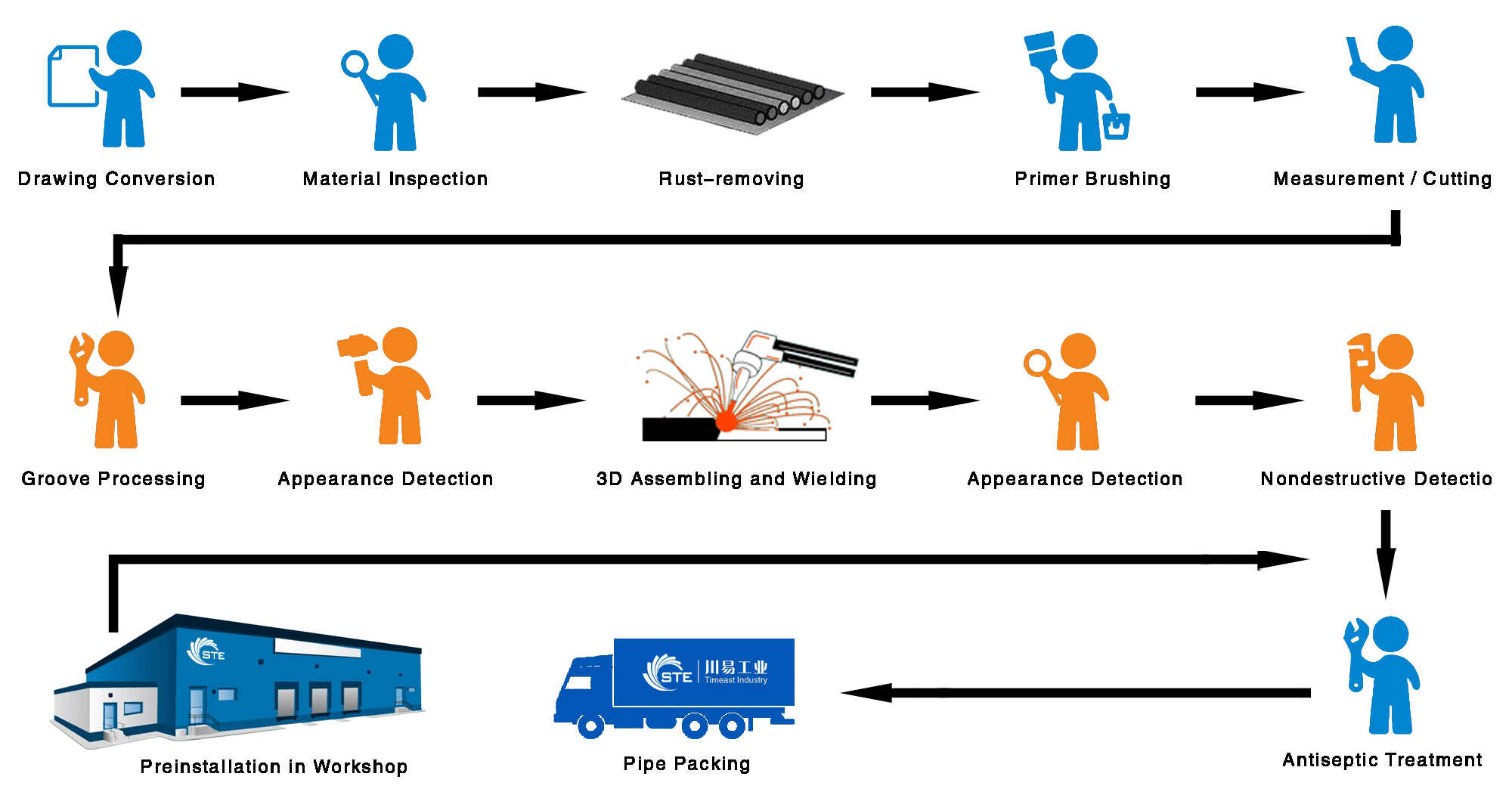

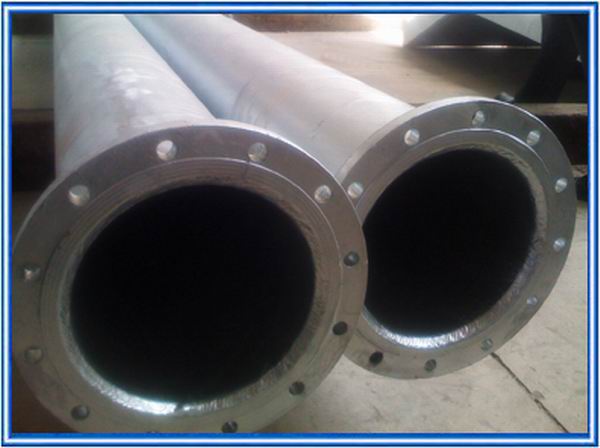

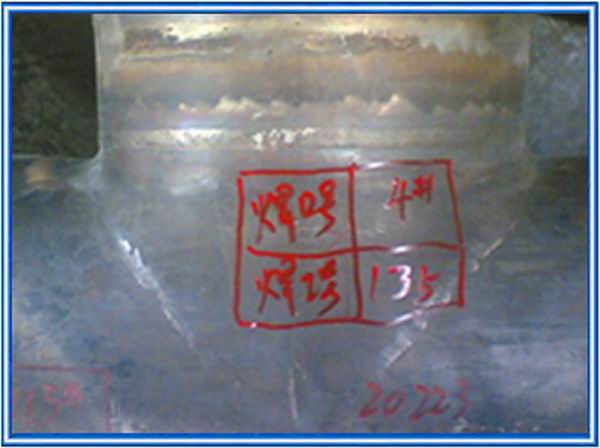

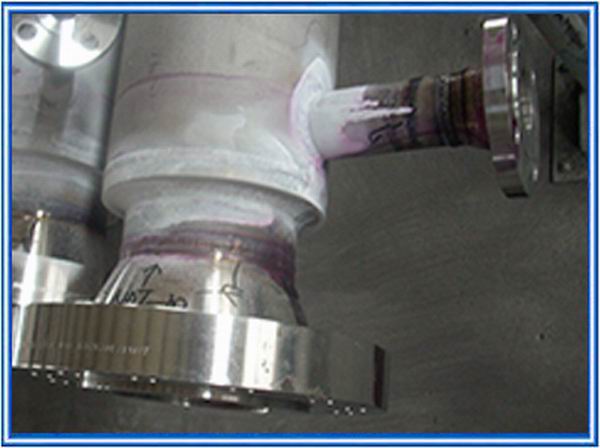

In the energy, petrochemical, mechanical and electrical industries, pressure piping is one of the keys to achieving engineering goals, STE's provides all walks of life with all types of pressure piping fabrication in the shop and on-site installation. Piping materials and construction requirements can be ASME/ASTM, PED, JIS, DIN, GB/TS and other standards. We are capable of performing all the processes required for piping operations, including material procurement, cutting and machining, forming, welding, painting, pipe support fabrication and on-site installation. The company has 5S and 6S welders certified by ASME, PED, etc. and is good at prefabricating pipes made of high strength carbon steel, special alloy steel and various types of stainless steel.

| PROJECT NAME | WORKING SCOPE | CONTRACTOR | END USER / DESTINATION | DATE |

| Pipe prefabricaiton | ORMAT | TURKEY/ AMERICAN/ NEW ZEALAND / KENYA | Long Term | |

| Pipe prefabricaiton | DESMI | CHINA | Long Term | |

| VCR Project | VCR Pipeline fabrication | Morimatsu | Canada | 2024 |

| Drury Petfood Steam Supply Manifolds | Drury Petfood Steam Supply Manifolds | Hongshan Machinery | Australia | 2024 |

| HP HTL cycle piping | HP HTL cycle piping | LAVA | Israel | 2024 |

| Tremco PSA42 | Pipe prefabricaiton | ALATC | CHINA | 2023 |

| Israel Desalination Plant | Pipe prefabricaiton | GES / FRC | GES / ISRAEL | 2023 |

| Pipe prefabricaiton | AIR LIQUIDE / GSP | USA | 2023 | |

| Samsung Austin TSA 12 | Pipe prefabricaiton | TAMUT | BAYSWATER / AUSTRALIA | 2023 |

| NEOM PROJECT | Copper-nickel alloy pipe prefabricaiton | TYHOO | SHELL / SAUDI ARABIA | 2023 |

| Pipe prefabricaiton | CSM | PMI / CUBA | 2023 | |

| Pipe prefabricaiton | TONE ENGINEERING CORPORATION / KANZAL | MOZAMBIQUE | 2023 | |

| ChiMei 2x30MW GTG Cogeneration Plant | Pipe prefabricaiton | TOSHIBA | TAIWAN,/CHINA | 2022 |

| KARARA | Pipe prefabricaiton | METSO | AUSTRALIA | 2022 |

| GSI 110K DWT COT | Pipe prefabricaiton | CRYOSTAR | SOUTH KOREA | 2022 |

| MANYAR SMELTER | Pipe prefabricaiton | SHI FW | INDONESIA | 2022 |

| MATARBARI UlTRA SUPER CRITICAL COAL FIRED POWER PROJECT | Pipe prefabricaiton | TPSC | COAL POWER GENERATION COMPANY/BANGLADESH | 2021 |

| TORTUE FPSO PROJECT | Ss pipe prefabrication | TECHNIP / COSCO | BP/ SENEGAL | 2021 |

| Pipe prefabricaiton | SHI FW | KOREA | 2020 | |

| Pipe prefabricaiton | SUNTECH | JAPAN | 2019 | |

| C227 SGFL PROJECT | Sampling connection piping prefabrication | IKL | BENGAL | 2019 |

| DAESAN BIOMASS POWER PLANT PROJECT | Pipe prefabricaiton | SHI FW | KOREA | 2019 |

| Stack, piping material supply | HONEYWELL | MALAYSIA | 2019 | |

| GS DANGJIN BIOMASS #2 POWER PLANT PROJECT | Pipe prefabrication | SHI FW | KOREA | 2019 |

| Piping and support prefabrication | JIANGNAN SHIPYARD / TGE | CHINA | 2019 | |

| Ss pipe prefabrication | TGE | MITSUI/JAPAN | 2019 | |

| Pipe prefabrication | DANMY | EVONIK/ CHINA | 2019 | |

| Pipe prefabrication | GS-HYDRO CHINA | CHINA | 2018 | |

| TOSHIBA Y6 PROJECT | Pipe prefabrication | ALEJ | TOSHIBA/JAPAN | 2018 |

| Pipe prefabrication | SUZHOU PARKETECH | ZPC/CHINA | 2018 | |

| Subsea hose connector | CHANGCHUN GOLSUN | PDVSA/VENEZUELA | 2018 | |

| Pu1094 pipe prefabrication | DANMY | BASF/CHINA | 2018 | |

| AU3225A PROJECT | Pipe prefabrication and pipe support | TGE | JAPAN | 2018 |

| Pipe prefabricaiton | HOWDEN | OYU TOLGOI | 2017 | |

| G-2 PROJECT 1527A PROJECT | Alloy piping prefabrication | AMEC FOSTER WHEELER | HANWA | 2016 |

| G7101 VENT LINE PIPING PROJECT | Pipe prefabricaiton and materials supply | NOV-TUBOSCOPE | CNOOC | 2016 |

| NWR CANDII 1 PROJECT | Miter elbow with flow guide | AL-LURGI | CANADA | 2016 |

| High pressure mud manifold modification | NOV-TUBOSCOPE | NORWAY | 2016 | |

| HONGHUA TDS11SQ PROJECT | Guide track and vent pipe prefabricaiton | NOV-TUBOSCOPE | NORWAY | 2015 |

| L6301 VENT LINE PIPING PROJECT | Pipe prefabricaiton and materials supply | NOV-TUBOSCOPE | NORWAY | 2015 |

| SOFTENED WATER TREATMENT PROJECT | Ss pipe prefabricaiton and materials supply | HUA QIANG ENVIRONMENTAL PROTECTION | CHINA | 2015 |

| L6901 VENT LINE PROJECT | Pipe prefabricaiton and materials supply | NOV-TUBOSCOPE | NORWAY | 2015 |

| Pipe prefabricaiton and materials supply | GLORY | TOKUYAMA/MALAYSIA | 2015 | |

| Pipe prefabricaiton and materials supply | NFM/NHI | BRAZIL | 2015 | |

| HYSY943 PROJECT | Pipe prefabricaiton and materials supply for helicopter platform | ALUMI OFFSHORE/DSIC | CNOOC | 2015 |